The regular price is the current manufacturer's recommended price! FREE shipping for orders over EUR 41,67 within CZ+SK (PPLparcel)

Calipers are most commonly used in engineering, metalworking, but also in craft and workshop work. They are popular mainly for their accuracy and ease of use. This type of measuring tool should include a calibration certificate, which confirms that it has been checked and meets measurement standards. The certificate is issued by an accredited calibration laboratory.

How is a caliper used?

Using a caliper is simple, but measuring requires attention to achieve accurate results.

We must make sure that the scale is calibrated and checked and that it is not damaged in any way. We open and close the caliper to make sure that the movement is smooth. Next, we place the object we want to measure between the arm and the jaw of the caliper. We check whether the object is placed evenly. The jaws must also not press too hard to avoid deformation.

We use both scales for measurement, we read millimeters on the main scale and hundredths of a millimeter on the lower scale, which is why we are able to measure the exact dimension with a caliper.

The lower jaws are used to determine the external dimensions of the part, the upper jaws are used to determine the internal dimensions.

We handle the caliper carefully. For example, it should not fall on a hard surface, because then its accuracy is no longer guaranteed.

What are the types of calipers?

With ordinary calipers, dimensions can be measured in the range from 0 to 150 - 300 mm. Workshop calipers for industrial use with a range of up to 4 meters are also produced.

It is also important to pay attention to the accuracy class so that it meets the needs of the specific application. The basic and sufficient accuracy for home conditions is 0.02 mm, i.e. two hundredths of a millimeter.

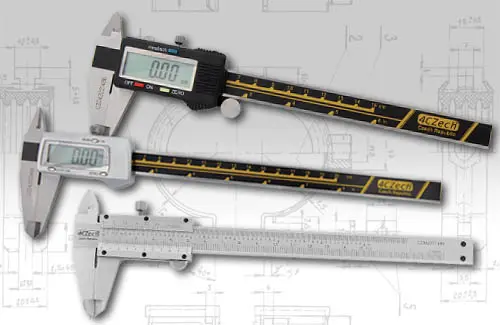

Calipers are further divided into mechanical (analog) and digital.

A digital caliper is very easy to use. All measured values can be read on the display and, in addition, you can select your own “0” on the scale. We can choose between different units of measurement, such as millimeters, centimeters, inches or even imperial units in the case of calipers designed for markets using this system. They differ from analog ones in that they do not have a vernier and their fixed and sliding parts function as magnetic, inductive or capacitive distance sensors. They also have various additional functions, such as diameter measurement, depth measurement, statistical functions, zeroing function or measurement memory. We also have to think about spare batteries - the law of consent clearly states that they will always run out when the shops are closed or when it is least convenient for us. Analog calipers do not have such restrictions.

Analog calipers are valued for their durability, reliability and ease of use. They are used in many places, both in industrial work, workshops and in technical education. In the vernier caliper, the basic part is an arm with two moving parts. One on a fixed main scale and the other on a sliding vernier scale. The vernier is a scale on a moving part that allows for a more accurate reading. They offer much higher accuracy compared to vernier calipers, which makes them a useful tool in laboratories, workshops and other places where measurement accuracy is important.

There are several processing variants. For example, we can find calipers with a locking screw or a locking button that fixes the measured value, forestry calipers with a dial indicator that has an adjustable dial with an adjusting screw, drafting calipers that are designed for drafting and use a carbide drafting tip, for recesses, solar calipers, or calipers with an IP 67 protection level that are dust and water resistant.

Other articles:

Měřící přístroj Zoller pomBasic

Patent na vylepšení vrtáků

Vrták CZ005 - Nový člen rodiny

Naše vrtáky jsou tématem bakalářské práce