The regular price is the current manufacturer's recommended price! FREE shipping for orders over EUR 41,67 within CZ+SK (PPLparcel)

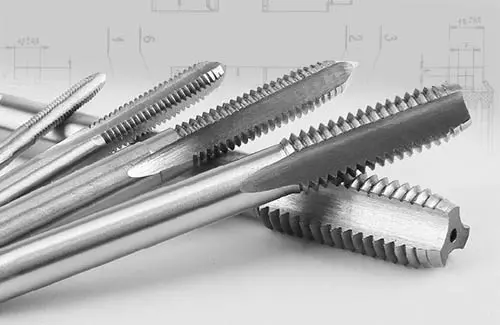

Taps are an essential tool for machining and are used to create internal threads in cylindrical holes. First, we need to determine what type of tap we want to work with. There are several divisions and we will now introduce them.

Hand taps are mostly used by DIYers and amateur craftsmen. They are clamped into a tap wrenches or a special wrench.

Taps are sold in sets of two or three pieces. The first, a pre-cutting tap marked with one stripe, is used to pre-cut threads. The second tap, the central one, has two stripes and is designed to tighten threads that have been pre-cut with a pre-cutting tap. The third tap, which no longer has a marking, is called a finishing tap, and it is used for final cleaning and completing a perfect thread.

Summary:

> Pre-cutting tap (one stripe)

> Center tap (two stripes)

> Finishing tap

DIVISION BY MATERIAL

They are usually made of high-quality steel, but not all steels are the same. First, we need to consider the hardness and resistance of the material we are going to thread. If you plan to cut a few threads or cut into softer materials, such as structural steels, copper, aluminum and their alloys, a carbon steel tap, marked CS, will suffice. However, if you want to make more threads or cut into harder materials, you need to choose a high-speed steel tap, marked HSS. For even harder materials, such as stainless steel, a tap marked HSSE or HSSCo5 is best, which is made of high-performance high-speed steel enriched with cobalt.

Summary:

> NO - carbon steel

> HSS - high-speed steel

> HSSE - high-performance high-speed steel

DIVISION BY THREAD TYPE

There are taps available for a wide range of thread profiles. We need to know what type of profile the thread has and which one we want to produce. However, the most commonly used are metric threads with the mark of M and metric threads with a fine pitch, marked with Mf. Then there are special taps with a pipe thread, with G marking, which are intended for creating threads on the ends of pipes, and taps with a Whitworth thread, marked W. We can also choose a tap with a unified coarse thread (UNC) or a tap with a unified fine thread (UNF).

Summary:

> M - Metric thread

> Mf - Metric fine thread

> G - Pipe thread

> W - Whitworth thread

> UNC - Unified coarse thread

> UNF - Unified fine thread

DIVISION BY SIZE

The sizes of taps are determined by the diameter of the hole into which the thread is cut and by the number of threads per inch. It should be noted that tap sizes are based on units of measurement, so they may vary depending on the country in which we use them.

TAP USAGE

Once we have chosen the right tap, we need to know how to handle it. The thread should be cut slowly and methodically to avoid overloading and damaging the tap. This is also not possible without regular cleaning, where excess metal and chips that can block thread cutting need to be removed. Furthermore, for long life and proper function, it is necessary to use a suitable lubricant when creating the thread. If everything is properly followed, perfect results will be achieved 100%.

This manual serves only as a guide and may not exactly correspond to all situations or specific conditions that may arise. It is recommended to adapt the procedure to the current circumstances and, if necessary, consult a sales representative.

More articles:

Jak nabrousit vrták

Testy vrtáků s novou geometrií

Brusný a řezný kotouč: Klíčový nástroj pro efektivní opracování materiálů