The regular price is the current manufacturer's recommended price! FREE shipping for orders over EUR 41,67 within CZ+SK (PPLparcel)

More articles:

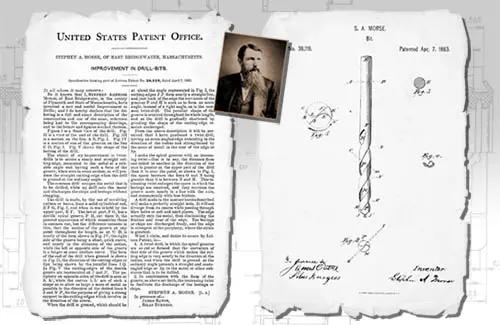

Testy vrtáků s novou geometrií

Vrták CZ005 - Nový člen rodiny

Naše vrtáky jsou tématem bakalářské práce