The regular price is the current manufacturer's recommended price! FREE shipping for orders over EUR 41,67 within CZ+SK (PPLparcel)

A spot weld is a connection between two metal parts created by applying high temperatures and pressure between them, which causes the metal to melt where the parts touch. This creates a strong connection at a specific point. These joints are usually found on cars, so drills are mainly used by auto body repairers.

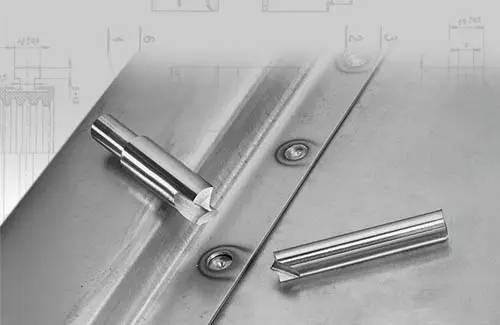

The drill has its own specific shape. It has a special tip that removes the weld without damaging the surrounding material. It can be single-ended or double-ended, and there is also a hole saw.

SINGLE-ENDED DRILL BIT

A single-ended drill bit has a cutting part on only one side and allows greater control over the drilling direction. It is suitable for small and medium welds. Ideal for fine and precise work.

DOUBLE-ENDED DRILL

A double-ended drill has cutting surfaces on both sides of the tip, so it can cut material both when rotating in one direction and when rotating in the opposite direction. It is fast, has a longer life and is suitable for larger welds. It is often used in industrial and manufacturing facilities where a large amount of work needs to be handled.

CORE DRILL

A core drill differs in that it has a larger diameter and focuses on removing more material around the weld. It is ideal for working with larger and heavier welds. The drill can quickly circle the spot weld and remove it without damaging the surrounding material. Individual crowns (milling cutters) and centering tips can also be purchased separately.

USE

You place the drill in the center of the spot weld and start drilling, thanks to the small centering tip and two 180-degree cutting edges, the drill does not deviate anywhere and drills the upper pinned sheet metal. They are used in hand drills.

MATERIAL

The welding spot drill bit is made of high-quality material, such as HSS or HSSCo5 high-speed steel. Thanks to this material, the drill bit is able to withstand the high temperatures generated during drilling and subsequently ensures effective weld removal.

The welding spot drill bit is therefore a practical tool for anyone who deals with dismantling or repairing metal structures that have been joined by spot welds.

Other articles:

AKU nářadí

Jaké jsou druhy vrtačkových sklíčidel?

Jak nabrousit vrták

Vrtání do dřeva