The regular price is the current manufacturer's recommended price! FREE shipping for orders over EUR 41,67 within CZ+SK (PPLparcel)

The most obvious difference in the design of a step drill will probably be the type of flute. This can be either straight or spiral. With a straight flute, more skilled craftsmen have the opportunity to sharpen their drill with a little skill even in the conditions of a home workshop. With a spiral flute, you get a positive cutting angle, which is more favorable for the performance and life of the blade. However, it is better to entrust the resharpening of a drill with a spiral flute to tool sharpening specialists who have the appropriate machinery and sufficient experience.

Another difference may be in the design of the clamping shank. When the drill shank is cylindrical, it is often equipped with three 120° flats around the circumference to prevent the drill from spinning in the drill chuck. Some drills have a ¼” (6.35mm) hexagonal shank so that they can be clamped into bit holders. In that case, I would recommend using a bit holder with a safety catch to avoid surprises, as the drill might not hold well in the magnetic holder and could fall out during use.

Each diameter of the step drill comes in many variations of the range and in the differences between the individual steps. The most commonly used seem to be drills from four or six millimeters to twenty or thirty millimeters. The graduation is then usually in millimeters, or in even diameters, but also in odd numbers. However, this is not a strict rule and drills whose maximum diameter is larger tend to have smaller diameters graduated in larger steps. You may also come across a drill that has steps adapted, for example, to electrical bushings used in switchboards, and their graduation has diameters in decimal places.

The height of the individual steps in turn determines how thick the material can be drilled. Between the individual steps there is a pitch to the next diameter, which can be used to deburr the drilled hole.

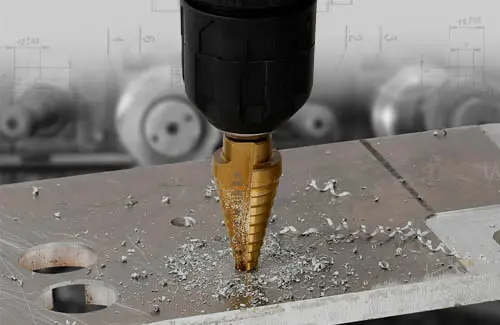

It is intended for use in cordless drills due to the speed range. When drilling, higher speeds can be used, but as we move to higher diameters, the speed must be gradually reduced. To extend the performance and life of the blade, as with any drilling, it is good to use a suitable cutting oil or paste.

Other articles:

Jak vybrat vhodný pilník nejen do dílny?

Pilníky na ostření řetězů motorových pil

Vrtání do dřeva

Jak vybrat správný ruční závitník?