The regular price is the current manufacturer's recommended price! FREE shipping for orders over EUR 41,67 within CZ+SK (PPLparcel)

The SDS clamping (Special Direct System) was originally developed by company Bosch and it is still used as standard for its practicality (quick tool change without the need for additional equipment) in the field of power tools. The tool is simply inserted and turned, thereby automatically securing it. SDS chisels are used primarily for demolition and demolition work on hard materials = concrete, bricks, masonry, tiles, stone, sandstone, etc.

The most common clamping standards are SDS-Plus and SDS-Max. They differ in their size:

• SDS-Plus:

For lighter tools and common construction work (demolition work, cutting grooves, etc.), has a shank diameter of 10 mm and 2 longitudinal grooves.

• SDS-Max:

For heavier tools and more complicated and demanding construction work (large-scale demolition work, rock removal, etc.), the shank has a diameter of 18 mm and 3 longitudinal grooves.

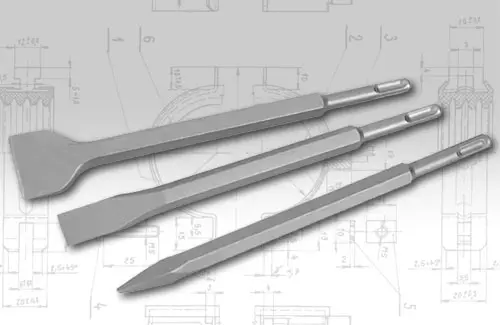

Types of SDS chisels:

1. Flat - chiseling flat surfaces, grooving

2. Pointed - breaking and demolition, creating cracks

3. Scaling - greater material removal on the surface

4. Curved for tiles - removing tiles

5. Wide scaling- even wider than spade, even greater material removal on the surface

6. Hollow/grooving - creating grooves in concrete/bricks (for cables)

7. Wing - supplemented with "wings" that expand the working surface of the chisel, used to create wider grooves

8. Slotting - roughening and structuring the surface

9. Bush hammer - stone processing with a head with square teeth

You can find all the mentioned types of chisels in our assortment.

Other articles:

Jak a čím vrtat do betonu?

4 rady, jak správně vrtat do dlažiček

Sady nářadí

Dílenské svěráky