The regular price is the current manufacturer's recommended price! FREE shipping for orders over EUR 41,67 within CZ+SK (PPLparcel)

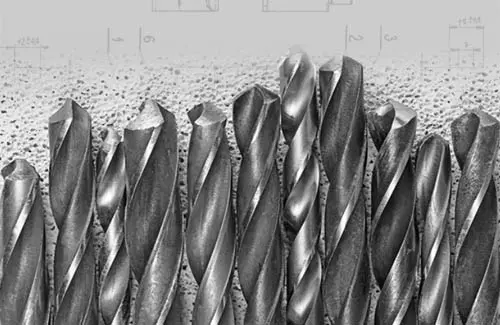

Both types of drills are made of high-speed steel, have the same length dimensions and also have the same heat treatment /hardening/. However, the main difference is in the manufacturing process.

Roll forged drills

These drills are manufactured by hot forming. This process causes a greater dispersion of dimensions than in fully ground drills. Therefore, if the user is not too keen on drilling accuracy, roll forged drills are ideal for him. On the contrary, the forming process allows for greater stability and rigidity when drilling. They are mainly used in applications in hard conditions, especially with the use of hand drills without a guide bush.

We offer roll forged drills from 0.20 mm to 25 mm in diameter, packaged in plastic pouches or quadropacks, oxidized - black finish, in the length dimensions DIN 338 /standard length/ and DIN 340 /extended length/.

Fully ground drills

The profile of fully ground drills is produced by grinding discs into already heat-treated (hardened) material. We call this process grinding. The shape of the helix is calculated so that the drilling quality is as good as possible (both the accuracy of the drilled hole and the service life of the drill). Therefore, these drills are chosen for operations that require higher accuracy and precision. They are used in both manual and machine drilling. These drills can also be supplied with various coatings to further increase their performance and extend their service life. More about coating options here: Tool coatings

We offer ground drills from diameter 00.12 mm to diameter 20 mm, shiny - silver finish, in length dimensions DIN 338 /standard length/, DIN 340 /extended length/, DIN 1869 /extra long length/.

Other articles:

Vrtáky s kuželovou stopkou

Jaké jsou druhy vrtáků?

Pracovní obuv

Zástrčné klíče