The regular price is the current manufacturer's recommended price! FREE shipping for orders over EUR 41,67 within CZ+SK (PPLparcel)

There are several types of measuring instruments, each suitable for a different activity. They can be divided according to different criteria, for example, according to the measurement principle or according to the specific type of measured parameter.

1) According to the measurement principle

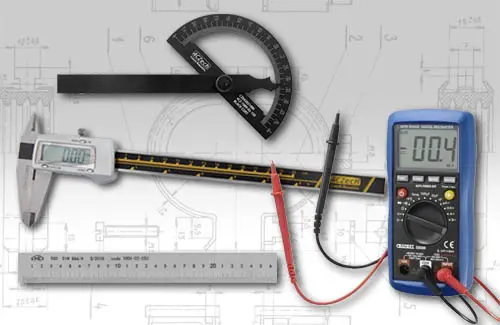

- mechanical measuring instruments (use mechanical principles for measurement, for example, calipers, micrometers, gauges)

- electronic measuring instruments (use electrical circuits and sensors, for example, digital multimeters, laser measuring instruments, thermometers with digital output)

- optical measuring instruments (measuring instruments that use optical principles, such as light, reflections. For example, laser measuring instruments, interferometers)

2) According to the type of measured parameter

- length (for example, tapes, micrometers, calipers)

- temperature (mercury, digital and infrared thermometers)

- weight (scales, dynamometers, hydrometers)

- pressure (manometers, pressure sensors)

- voltage and current (voltmeters, ammeters, multimeters)

- volume (gauges for container capacities)

- speed and flow (speedometers, flowmeters)

Vernier calipers have a very wide range of uses. They allow you to measure the length of a small pipe, a machine part or an electronic component. More in our article: Calipers/Callipers

If we want to verify not only the length, but also the correct angle, we can choose squares and protractors, which are essential for every craftsman.

Dial indicators also have an important function, checking deviations from the prescribed measurement to hundredths or thousandths of a millimeter.

Another very useful tool in production are drawing rulers, templates and needles. They are characterized by a precise shape.

We have selected more articles for you: