The regular price is the current manufacturer's recommended price! FREE shipping for orders over EUR 41,67 within CZ+SK (PPLparcel)

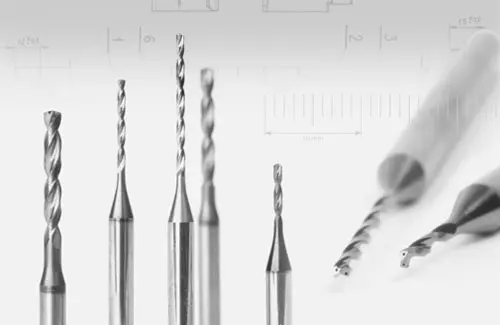

What is a micro drill?

Drills with a reinforced cylindrical shank, for drilling into common metal and non-metal materials in the field of model making, fine mechanics, etc.

Micro drills are designed for drilling into common metal and non-metal materials. The drills are particularly suitable for fine mechanics, model making, etc. The advantage is the possibility of universal clamping without the need for a large number of clamping collets. Only a collet Ø 1.0 mm and Ø 1.5 mm is required.

They are made of selected high-quality steel. Purposeful and stable construction of the shank and drill from one piece. Optimal accuracy of centered running. Thanks to the appropriate hardness, long service life while maintaining flexibility. For processing metals, non-ferrous metals, plastics, printed circuit boards, soft and hard wood. Working speed: approx. 8,000/min for soft material, approx. 3,000/min for hard material. Suitable for metal, plastics, printed circuit boards and wood.

Technical parameters:

ČSN 221191 HSS - DIN 1899A RN HSS

Drills are manufactured by grinding from 0.25mm to 1.45mm by 0.10mm

Helix pitch: λ = 25° ÷ 30°

Point angle: ε = 118°

Drilling depth: 3 x D

Reinforced shank diameter:

ØD < 0.8 mm ~Ød=1.0 mm

ØD ≥ 0.8 mm ~Ød=1.5 mm

Maximum speed: 45,000 rpm

How to work with microdrills?

Micro drills are used with a hand or bench drill. This is very careful and precise work, because micro drills are very fragile tools that can easily break. When drilling, a lower drilling speed and, if possible, constant pressure are usually chosen.

Working with micro drills requires a lot of patience and practice. That is why you will not normally encounter these drills in ordinary DIY activities. However, they are a common part of modern industry and research. Micro drills also have their applications in the healthcare sector.

We selected more articles for you: